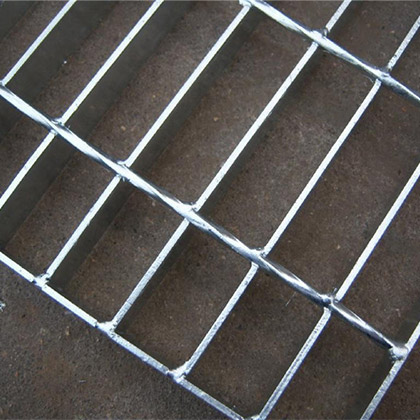

Steel grating is made by welding with flat steel and bars with certain distances. It goes through cutting, opening, edging and other processes. The products enjoy the features of high strength, light structure, high bearing, convenience for loading and other properties. The hot dipped zinc coating gives the product excellent anti-corrosion resistance.

Material: carbon steel,stainless steel,low carbon steel,high carbon steel

Steel grating is widely used in the platform, corridor, for build floor,bridge, upholster,well covers, stairs, fencing for petroleum, chemical, power plant, waste treatment plant, civil engineering projects and environmental projects.

| Common specification of Steel grating | |

| Material Standard | ASTM A36, A1011, A569, Q235, S275JR,Stainless steel 304, Mild steel & Low carbon steel, etc |

| Bearing Bar (width*thickness) |

25×3, 25×4, 25×4.5, 25×5, 30×3, 30×4, 30×4.5, 30×5, 32×5, 40×5, 50×5, 65×5, 75×6, 75×10…..100 x10mm etc; I bar: 25x5x3, 30x5x3, 32x5x3, 40x5x3 etc US standard: 1”x3/16”, 1 1/4”x3/16”, 1 1/2”x3/16”, 1”x1/4”,1 1/4”x1/4”, 1 1/2”x1/4”, 1”x1/8”, 1 1/4”x1/8”, 1 1/2”x1/8” etc |

| Bearing Bar Pitch | 12.5, 15, 20, 23.85, 25, 30, 30.16, 30.3,32.5, 34.3, 35, 38.1, 40, 41.25, 60, 80mm etc. US standard: 19-w-4, 15-w-4, 11-w-4, 19-w-2, 15-w-2 etc. |

| Twisted Cross Bar Pitch | 38.1, 50, 60, 76, 80, 100, 101.6, 120mm, 2” & 4” etc |

| Surface treatment | untreated(black), hot-dipped galvanized ,powder coated, electroplate, painting or as per customers’ requirement. |

| Grating Style | Plain / Smooth, Serrated /teeth, I bar, serrated I bar |

| Remarks: Other sizes also can be customized according to customers’ requirement. | |